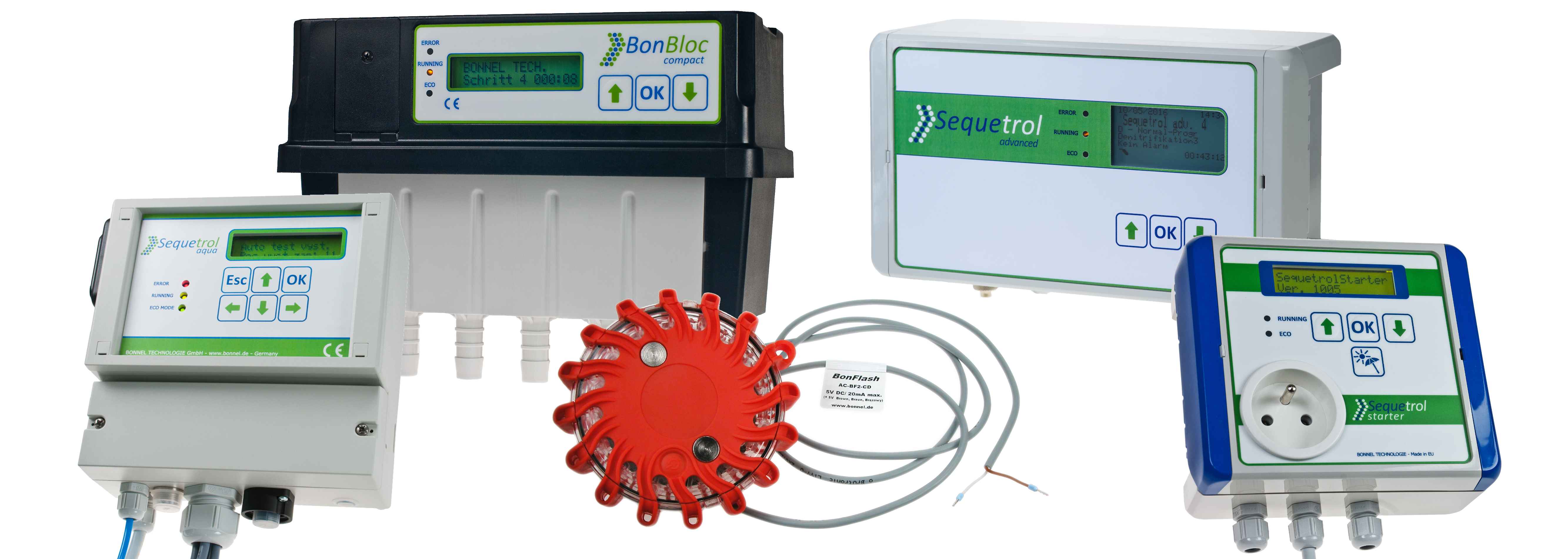

Compact and reasonably priced control unit with LCD for decentralized SBR sewage treatment plants

Compact and reasonably priced control unit with LCD for decentralized SBR sewage treatment plants

HIGHLIGHTS

- Easily programmable control unit for small SBR treatment plants

- Adjusting of the step times can be done on-site using three buttons on the printed circuit board

- Keeps record of last performed step in an event of mains failure

- 5 relay outputs (230V)

- Digital input for float switch

- Acoustic alarm and mains failure signalization

- Also available as special version for price-sensitive Pump-SBR wwtp

Why use the Sequetrol compact control unit?

- Compact control unit that stands out due to its price performance ratio

- Backlit 2x16 character LCD allows to have step names, alarm messages and operating hours clearly displayed during operation

- Even people without programming experience can easily create a program by editing an Excel® spreadsheet

- Individually equipped (display, keypad, connectors) according to customer requirements

- Integrated operating hours counter

- Automatic release of residual pressure in the valve unit

- Updateable firmware and software

- Design of the front-panel according to customer preference

Equipment

The extent of the system functionality and the de-sign of the front panel of the Sequetrol® compact LCD control unit can be tailored to match your individual needs.

The Sequetrol® compact LCD is also available with features, such as, acoustic signaling of predefined conditions, a sequence program permanently stored in the EEPROM, and a set of batteries (optional NiMH rechargeable batteries) to ensure continuous signaling during power outage.

The built-in backlit 2x16 character LCD allows to have step names, alarm messages, operating hours and other user specific information, clearly displayed during operation.

When the control sequence is interrupted due to mains failure, the unit will automatically resume operation with the last unfinished step instead of restarting the program.

Utilizing the three buttons on the circuit board, the sequence timing can be readjusted at the installation site, resulting in an increased flexibility in adapting the Sequetrol® compact LCD to the individual requirements of the particular plant.

Build-up of residual pressure in the valve unit is prevented by stopping the compressor before closing the valves. Timing is individually adjustable for each program step (0 - 14s).

Connections

Available digital input can be used to connect a float-switch or another sensor.

Up to 5 relay outputs for 230VAC offer a comfortable connection of solenoid valves, diaphragm compressors or other loads.

Programming

The programming process was developed especially with regard to the demands of a real decentralized SBR sewage treatment plant.

The control unit will be delivered ex-factory already preprogrammed according to customer requirements. Firmware updates and sequence program changes can be performed with the aid of an inexpensive programming device. This also makes the Sequetrol® compact LCD “future-proof” and ready for possible changes of the legal situation.

No programming experience or any special software is needed.

The sequence program can be easily created or modified using a ready-made spreadsheet table (Excel®).

TECHNICAL DATA

| Attribute | Value |

| Dimensions (l x w x h); weight | 155 mm x 133 mm x 76 mm; 0.70kg |

| Ambient temperature | -20°C to +55°C |

| Protection classification | IP 54 |

| Functions, sequence program, alarms | All according to customer request and requirement. Sequence programs are designed and adapted by the wastewater treatment plant manufacturer by means of an Excel®-chart |

| Display | Backlit B/W LCD, 2 x 16 characters |

| Signal-inputs | Digital input for float switch or other sensors |

| Data interface | RS-232 |

| Electrical output |

According to customer request, up to 8 relays 230V / 300VA |

| Power supply during mains failure | Standard camera battery, rechargeable batteries on request |

| Power supply | 230VAC, 1,5 VA max. |

DOWNLOADS

Please use our Contact form to order your control unit.

Read more about our other products and services HERE.

ČESKY

ČESKY  DEUTSCH

DEUTSCH  ENGLISH

ENGLISH